Design Optimization

Komaspec has extensive design for manufacturing experience we bring to bear on new product introduction projects, and new OEM products introduction projects working with customers to improve all aspects of the design, from reliability to repeatability to cost-effectiveness.

Prototyping

Komaspec offers access to a wide suit of prototyping technologies and options, including 3D printing, laser sintering in plastic and metal, vacuum molding, CNC, etc. in order to quickly iterate on part design or to validate product features, fit or function.

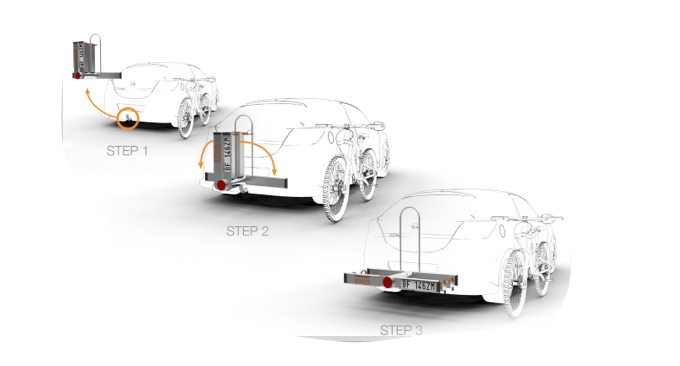

Pilot Productions

Komaspec conducts thorough debugging through the pilot and small batch production process – troubleshooting the product manufacturability, the production processes, jigs and ensuring manufacturing repeatability. We work with customers to document and resolve any issues or problems discovered during the course of the pilot, and ensure that mass production is as smooth as possible.

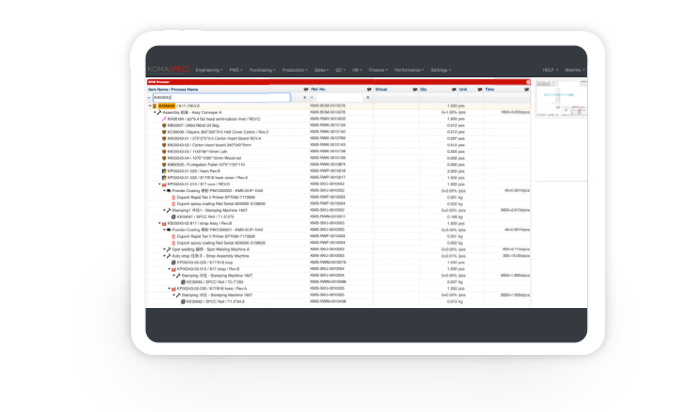

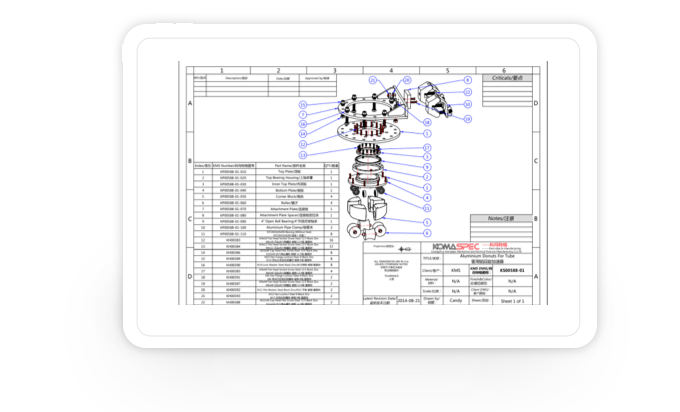

New Product Documentation

As part of the NPI process, we help to support customers with the development of new product documentation, including electronic, multi-level BOMs, detailed global drawings and assembly instructions, a well as utilizing quality tools and methodologies like FAIs, PPAP, CpK records, FMEA, electronic IQC records and more.

Do you have any questions about how we can work for you?