Our EMS Capabilities

PCBA Fabrication

PCBA Fabrication

Advanced Surface Mount Technology (SMT) and Through-Hole Technology (THT) for precise assembly.

Designing and manufacturing cable harnesses for various applications.

Reliable sourcing of high-quality components from trusted suppliers.

Inventory Management

Inventory Management

Streamlined inventory processes to minimize waste and maximize efficiency.

Prototyping

Prototyping

Rapid prototyping to ensure design validation and accelerated product development.

Testing & Quality Control

Testing & Quality Control

Comprehensive testing processes to ensure every product meets the highest quality standards.

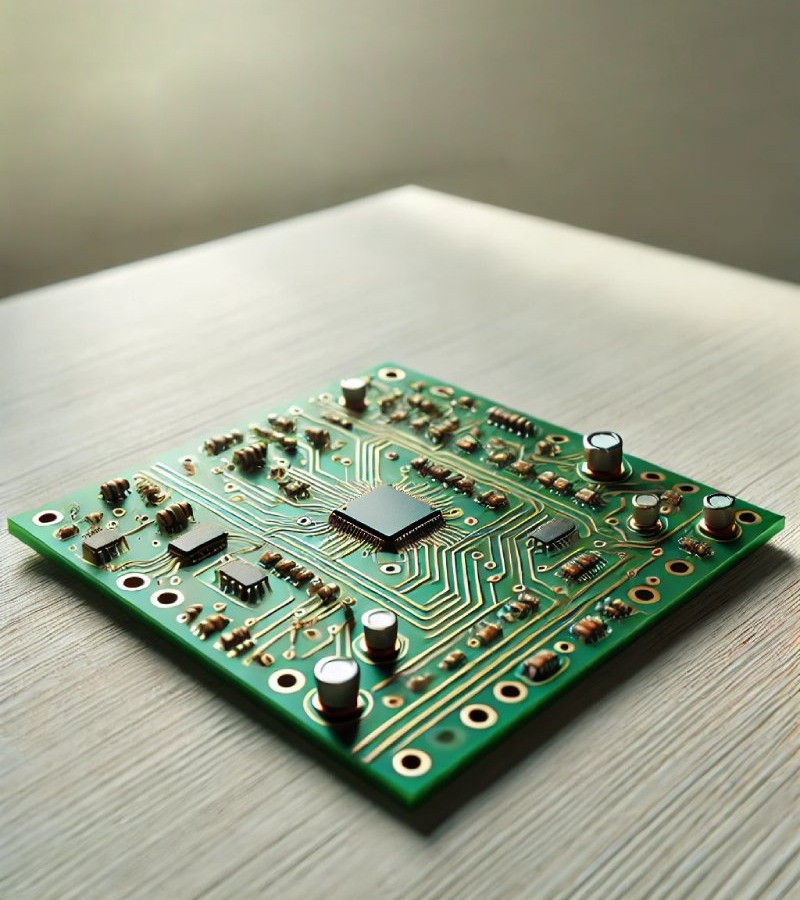

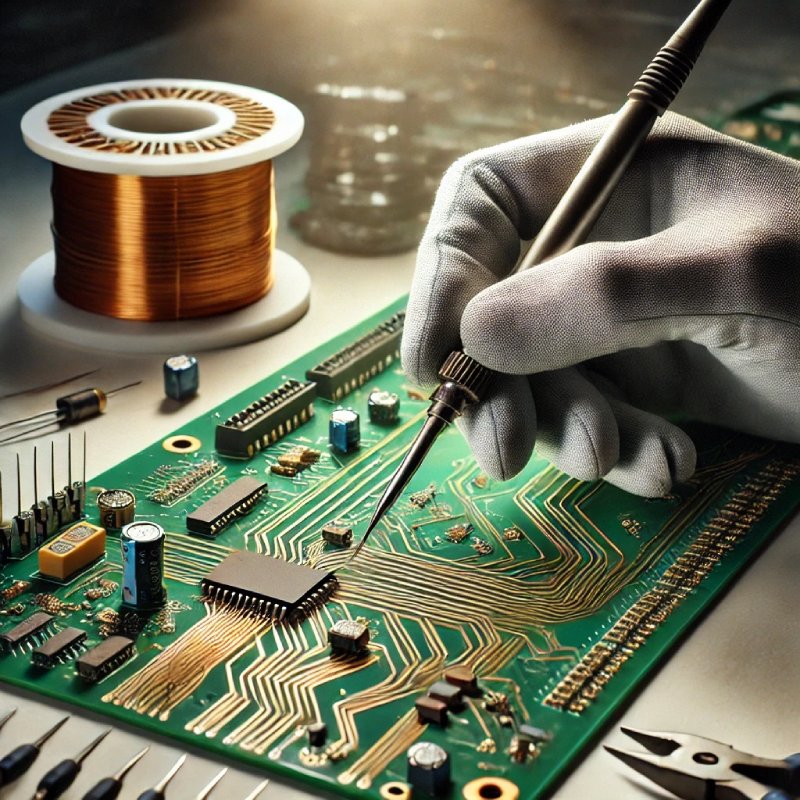

PCB Assembly Process

Komaspec supports both SMT and through hole printed circuit board assembly (PCBA) for customers with box build, electromechanical or other products in the most challenging applications. This means not only consistent support on design and BOM refinement, but comprehensive support to ensure consistent quality at the component and product level.

1. Solder Paste Stencil – Precise application of solder paste using thin stainless-steel stencils.

2. Pick and Place – Automated placement of components onto the PCB with high accuracy.

3. Reflow Soldering – Controlled heating processes to ensure strong, reliable connections between components and PCBs.

4. Inspection and Quality Control – 100% functional testing via jigs; X-ray, AOI, 2.5D, high-pot testing and other capabilities available.

5. Through-Hole Component Insertion – Both manual soldering for through-hole components and wave soldering / SMT placement for mass production.

6. Final Inspection and Functional Testing – Comprehensive testing to ensure electrical functionality, including voltage, current, and signal outputs.

Turnkey EMS Solutions & Capabilities

Beyond electronics manufacturing services, Komaspec provides integrated solutions, including:

• Engineering support and design services

• In-house tooling and plastic injection molding

• CNC machining and high-precision die casting

• Electrical assemblies and sub-assemblies

• Cable and wire harness assembly

• Rigorous testing capabilities

These complementary capabilities enable us to handle complex projects and deliver complete solutions to our clients.

Applications

Our electronics manufacturing services are designed to meet the needs of diverse industries, including:

-

• Agricultural: Agritech products, automated feeding systems, sensors, and support equipment.

-

• Commercial Appliances: Embedded control systems, user interface modules, and energy management devices.

-

• Industrial Equipment: PCBAs for automation, sensor suites, and heavy-duty equipment controls.

-

• IoT Devices: Sensing equipment, small-scale machine vision devices, monitoring systems.

-

• Mining: Durable electronics for harsh environments, including charging modules, IOT location devices, communication modules, and control equipment.

PCBA Fabrication Technology

Surface Mount Technology (SMT)

SMT is a precise, automated process for placing Surface Mount Devices (SMD) like resistors and transistors onto a PCB. It allows for compact, high-density designs, ensuring accuracy and efficiency in electronic assembly.

Through-Hole Technology (THT)

THT involves inserting component leads into drilled holes on a PCB and soldering them for strong connections. It is ideal for larger components like capacitors and relays, offering durability and reliability in demanding applications.

FAQs

Komaspec is offering turnkey electronics manufacturing services – which means essentially everything you need to ship an electrical product, Komaspec can provide. This means enclosure fabrication, custom cable harnesses, harness assembly, PCB assembly, box-builds, electromechanical sourcing, full assembly and testing services, etc.

Komaspec works with SMEs in a range of industries, but we have the deepest experience in non-consumer applications, with projects in mining, agritech, commercial appliances, IOT, automotive peripherals and industrial applications.

Komaspec offers reverse engineering services for existing boards, and can also provide off the shelf solutions for some product requirements, such as projects which require simple remote control functionality, WIFI, Bluetooth controls, power transformation, etc. In case a unique solution is required, Komaspec partners with both Western and Chinese engineering and design houses for custom PCBA design and testing.

For solutions where we are providing off-the-shelf designs, Komaspec will provide the necessary firmware to run the board. Komaspec does not offer custom firmware or software development in-house at the moment.

Partner with Komaspec for reliable, end-to-end Electronics Manufacturing Services. From custom cable and PCBA fabrication to assembly, testing, and quality assurance, we ensure every step is handled with precision and care. Our expertise and commitment to excellence help bring your product to market efficiently and effectively.