Precision Laser Cut Parts in Asia & North America

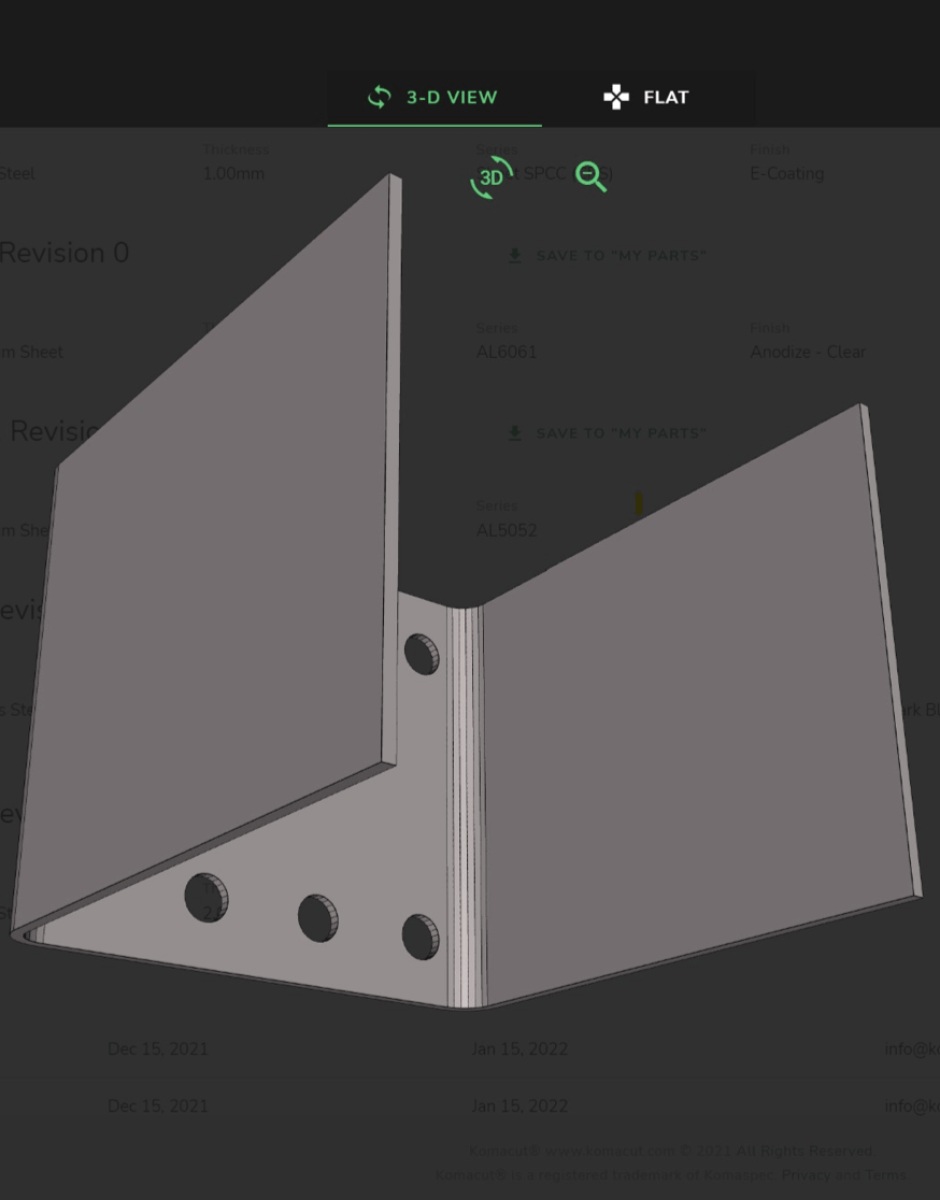

Komaspec produces thousands of laser cut parts each day to exacting customer requirements. We prioritize meeting your unique product specifications by leveraging our extensive knowledge and experience in the laser cutting industry.

Our state-of-the-art facilities have advanced, interconnected laser cutting equipment, enabling us to deliver exceptional components efficiently. With an extensive selection of material grades and thicknesses readily available, we guarantee swift turnaround times that cater to your project's timeline. Explore the table below for additional details:

Material

- • Aluminium (5052, 6061, 6063, 1060)

- • Carbon Steel (SPCC, HRS, SAPH440)

- • Stainless Steel (201, 301, 304)

- • Cold Galvanized Steel

Thickness

- • Stainless Steel: 0.5mm to 8.0mm

- • Steel: 0.5mm to 20.0mm

- • Aluminum: 0.5mm to 10.0mm

Equipment

- • Mitsubishi CO2 Laser Cutting 3kW

- • LVD Fiber Laser Cutting 8kW with auto loading material tower

- • AccurPress CNC Sheet Bending 100T - 6 Axis

- • LVD CNC Sheet Bending 80T - 9 Axis

- • LVD CNC Sheet Bending 80T - 6 Axis

- • LVD CNC Sheet Bending 24T - 5 Axis

- • Sheet Metal Drilling & Threading CNC

- • Automatic Plate Deburring

Surface Finishing

- • Powder Coating

- • Anodizing

- • Electro Coating

- • Trivalent Zinc Plating

- • Hot Dip Galvanized

- • Passivation

- • Dacromet

- • Sandblasting

Request a Free Consultation

Why Choose Us

Komaspec is offering a combination of advanced technology, expertise, and exceptional customer support. Our state-of-the-art equipment ensures precision and efficiency in producing laser cut parts for various applications. We work closely with you to understand your requirements and deliver customized solutions that meet your specific needs. With our expertise in various industries, we guarantee your laser cut parts will be manufactured to the highest quality standards.

• Personalized project management and consultation from our skilled engineers and technicians for timely communication and updates

• Seamless transition from prototyping to mass production

• Rapid turnaround times for your laser cut part needs

• Capability to handle complex geometries and a wide range of thicknesses, from 0.5 mm to 20.0 mm

• Parts size up to 1.5 meters by 3.0 meters, with automated deburring and other valued added services such as CNC bending, chamfering, threading and surface finishing

Contact Us

Real-Time Quotation & DFM Capabilities

Komaspec has spent years developing its proprietary laser part analysis engine, which allows us to offer instant quotes and DFM feedback to our customers (in partnership with our sister company Komacut.com). This allows our engineers to rapidly iterate and turn around sheet metal quotations and prototypes, which offering unparalleled speed and quoting accuracy. Our state of the art MES system allows us to feed real-time data back into our system, ensuring accurate pricing, planning and unmatched efficiency.

• Instant DFM and quotation capabilities

• Streamlined process for faster project planning and execution

• Experienced sheet metal engineers and draftsmen to provide expert advice

• Simplified order management and tracking for your convenience

• Enhanced efficiency and reduced lead times with our integrated system

Try Komacut

Our Manufacturing Solutions

Laser Cutting

Laser Cutting

Precision laser cutting and CNC bending manufacturing services.

Laser Cutting Assembly

Assembly

Contract manufacturing services for assembly of finished products.

Assembly Stamping

Stamping

Stamping and progressive-die services for medium- to high-volume orders.

Stamping Sheet Metal Fabrication

Sheet Metal Fabrication

Customized sheet metal fabrication services for medium- to high-volume orders.

Sheet Metal Fabrication Pipe and Tube Processing

Pipe and Tube Processing

Pipe and tube processing for medium- to high-volume orders.

Pipe and Tube Processing Plastic Injection

Plastic Injection

Manufacturing and assembly for medium- to high-volume orders.

Plastic Injection

Don't miss out on the opportunity to experience the difference that advanced technology and industry expertise can make for your business. Contact us today to transform your designs into reality.

Get a Free Quote

Laser Cutting FAQs

- • Higher precision and accuracy for intricate designs

- • Greater repeatability and consistency across large-scale projects

- • Faster production times compared to traditional cutting methods

- • Capability to handle complex geometries and tight tolerances

- • Minimal material waste due to the narrow kerf width

- • Contactless cutting process, reducing the risk of material deformation

Komaspec's advanced laser cutting technology is compatible with a wide range of materials, including stainless steel, aluminum and more. Our equipment is designed to handle various thicknesses and applications, providing precision and efficiency for your projects. Contact us for detailed information.

Komaspec has experience serving diverse industries, such as automotive, agriculture, and construction among others. Our skilled team is equipped to handle a variety of applications, ensuring your laser cut parts meet the specific requirements of your industry. Read more here.

Depending on your specific requirements you can either contact us for a quotation or use our online quotation engine.

Yes, Komaspec is able to handle your shipment for products manufactured by Komaspec. We have a network of freight forwarders whom we work with for shipments to various countries.

Lean manufacturing, small to medium size batch manufacturing, vertical integration in the supply chain and long-term relationships with our suppliers enable us to have quick changeover setups and responses. Additionally, we care about our customers and take their needs and problems as ours and endeavor to resolve any issues promptly.

Should you need any references, please contact us at technicalsales@komaspec.com and we will be pleased to provide you with a reference list upon request.